Powerful protection in every nook and cranny

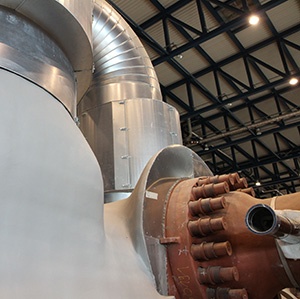

In power plants, the right thermal insulation for the turbines plays an essential role in keeping the processes running efficiently. And the performance of the turbines themselves can be optimized by selecting the right insulation method. The HardCAP system developed by G+H Insulation is a positive-fit, homogenous and jointless spray insulation which can be adapted to suit the individual requirements and thus ensures effective thermal insulation – even for turbines with complex contours.

Versatile and adaptable protection

The mixture of mineral-wool and cement used in the spray insulation is applied directly onto the turbine casing with the required layer thickness and develops high strength. A subsequently applied hard jacket prevents oil and water from penetrating into the insulation, reduces the risk of fire and thus assures the safe operation of the plant. It also protects against mechanical damage and can be stepped on. The coating provides a choice of coloring options and clean, dust-free, easy-clean surfaces.

The spray insulation with the HardCAP system is sufficiently elastic to allow thermal expansion and thus prevents tension cracks from forming as the temperature fluctuates. Since absolutely no joints are formed in the first place, the system minimizes thermal bridges and allows the turbine casing to heat up evenly. Due to its comparatively low thermal conductivity, the turbine insulation has a better insulating effect and thus ensures greater efficiency. Furthermore, the HardCAP system has a positive effect with regard to sound insulation. It bonds to all load-bearing surfaces, can be applied even in areas that are difficult to reach, and is also ideal for repairing old thermal insulation.